Electric motors are central to the functionality of modern vehicles, industrial machinery, and renewable energy systems. With global trends emphasizing energy efficiency, emissions reduction, and electrification, the demand for high-performance motors has risen sharply. Automotive electrification, including electric vehicles (EVs) and hybrid powertrains, requires motors that deliver high torque, reliability, and minimal energy loss. Similarly, industrial motors used in pumps, compressors, and automation systems must operate efficiently under continuous load conditions to meet energy regulations and reduce operational costs.

Motor efficiency is strongly influenced by the core components, particularly the laminations that form the rotor and stator cores. Premium Motor Laminations are engineered to provide superior magnetic performance, reduced energy loss, and long-term durability. Their adoption has become critical as manufacturers strive to meet stricter efficiency standards, including IE3 and IE4 for industrial motors and increasingly demanding automotive specifications.

Motor laminations act as the magnetic pathway for AC and DC motors. They are responsible for guiding magnetic flux while minimizing energy losses, which primarily occur through eddy currents and hysteresis. Key concepts include:

Eddy Current Reduction: Laminations divide the magnetic core into thin insulated sheets, reducing circulating currents that cause energy loss and heat buildup.

Hysteresis Minimization: High-grade electrical steel with optimal silicon content lowers resistance to repeated magnetization cycles, reducing thermal stress and improving efficiency.

Mechanical Integrity: Laminations must withstand rotational forces, thermal expansion, and vibration without deformation, ensuring stable performance over time.

Advancements in material science and manufacturing technology, such as precision cold-rolling, grain-oriented steel, and advanced insulation coatings, have enabled the production of laminations that meet the high-performance demands of automotive and industrial motors.

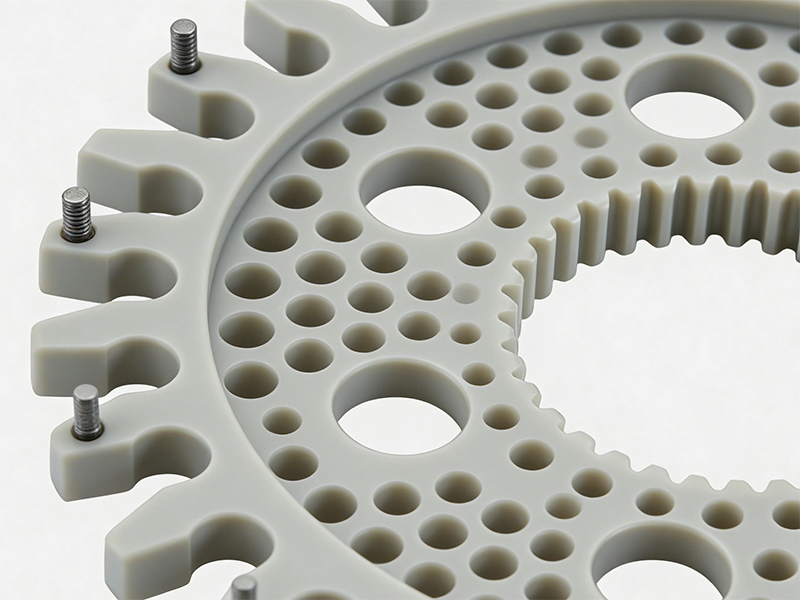

Premium motor laminations are thin, flat sheets stacked to form the rotor and stator cores. Each sheet contains slots for winding placement and is designed to maintain a continuous magnetic path with minimal air gaps. Proper alignment and stacking are essential to reduce vibration, noise, and energy losses, particularly in high-speed automotive and industrial motors.

Electrical steel with 2–3% silicon content is commonly used for premium laminations. The silicon enhances magnetic permeability while minimizing hysteresis losses. Non-grain-oriented steel is typically applied in motors requiring flux in multiple directions, whereas grain-oriented steel may be used in specialized DC motors for optimal directional magnetic performance. Advanced coatings, such as phosphate, oxide, or polymer layers, provide electrical insulation between sheets, preventing short circuits and reducing eddy currents.

The production of premium motor laminations involves several precision-controlled steps:

Cold Rolling: Electrical steel is rolled to achieve precise thickness, uniformity, and smooth surface finish.

Annealing: Heat treatment relieves internal stress, improves magnetic properties, and stabilizes the steel for stamping.

Cutting and Stamping: Laser cutting or mechanical stamping ensures accurate geometries with minimal burrs. Precision in slot and edge design is critical for stacking efficiency.

Insulation Coating: Laminations are coated with a thin, uniform layer to electrically isolate sheets and provide thermal resilience.

Stacking and Core Assembly: Laminations are assembled with tight tolerances to form rotor and stator cores, maintaining alignment and structural integrity.

Premium laminations provide:

Reduced Core Losses: Lower eddy current and hysteresis losses improve motor efficiency and thermal management.

Mechanical Reliability: High tensile strength and dimensional accuracy reduce vibration and structural fatigue.

Extended Lifespan: Durable coatings and high-quality steel maintain performance under demanding operational cycles.

Energy Efficiency: Optimized magnetic flux pathways reduce heat generation, minimizing cooling requirements and operational costs.

The efficiency and reliability of motor laminations depend on:

Material Consistency: Deviations in silicon content, alloy composition, or thickness can negatively affect magnetic performance.

Precision in Thickness: Even minor variations can increase core losses and reduce efficiency.

Insulation Quality: Imperfect or inconsistent coatings can lead to electrical shorts, overheating, and early failure.

Stacking Accuracy: Misaligned laminations cause flux leakage, vibration, and increased mechanical stress.

Surface Finish: Burrs or rough edges compromise stacking and flux distribution.

Implementing robust quality control, including magnetic property testing, dimensional inspection, and coating verification, is essential to producing reliable premium laminations.

Selecting reliable suppliers is critical for high-quality motor production. Considerations include:

Material Certification: Compliance with IEC, ASTM, or JIS ensures consistent magnetic and mechanical properties.

Manufacturing Capability: Advanced rolling, stamping, coating, and annealing processes are necessary for thin, durable laminations.

Consistency and Yield: Suppliers with low defect rates prevent production delays and maintain performance standards.

Technical Support: Engineering assistance for material selection, lamination design, and testing optimizes motor performance.

Logistics Reliability: Timely delivery and inventory management support uninterrupted production schedules.

Despite technological advancements, challenges remain:

Thinness vs. Durability: Ultra-thin laminations improve efficiency but are more susceptible to damage during handling and assembly.

Cost Management: High-quality steel and advanced coatings increase material costs, requiring design optimization.

Operational Stress: Motors operating under high torque or continuous industrial loads face thermal and mechanical stress.

Supply Constraints: Limited availability of premium laminations can affect production schedules, especially in automotive EV manufacturing.

Addressing these challenges requires precise engineering, stringent quality assurance, and reliable supplier relationships.

Premium motor laminations are critical in:

Automotive Motors: EV traction motors and hybrid powertrains rely on high-efficiency laminations for torque, thermal stability, and energy savings.

Industrial Motors: Pumps, compressors, conveyors, and CNC machines benefit from improved reliability and reduced operational costs.

HVAC Systems: Fans, compressors, and blowers achieve energy efficiency and reduced noise.

Renewable Energy Applications: Wind turbines and hydroelectric generators use low-loss laminations for high power conversion efficiency.

Consumer Appliances: Washing machines, refrigerators, and air conditioners leverage laminations to reduce energy consumption and improve reliability.

In each application, premium laminations enhance motor performance, energy efficiency, and long-term durability.

Key trends in premium motor laminations include:

Ultra-Thin Laminations: Sheets below 0.20 mm reduce eddy current losses while maintaining mechanical strength.

Advanced Materials: Amorphous and nanocrystalline steel are emerging to minimize hysteresis losses for high-performance applications.

Simulation-Based Design: Magnetic, thermal, and mechanical modeling optimizes lamination geometry and motor efficiency before production.

Sustainable Manufacturing: Low-emission steel production and eco-friendly insulation coatings align with global environmental regulations.

High-Speed EV Motors: Increasing demand for lightweight, durable laminations in electric propulsion and industrial high-speed motors.

These trends indicate a move toward thinner, stronger, and more precise laminations to meet evolving efficiency and performance requirements.

Q1: Why are premium laminations critical for motor performance?

They reduce energy losses, enhance thermal management, and provide mechanical stability, directly affecting motor efficiency and longevity.

Q2: What materials are typically used?

High-quality electrical steel with 2–3% silicon content, coated with insulating layers to prevent eddy currents and short circuits.

Q3: How does lamination thickness influence efficiency?

Thinner laminations reduce energy losses but require careful handling and precise stacking to maintain durability.

Q4: Which industries benefit most?

Automotive, industrial manufacturing, HVAC, renewable energy, and high-performance appliances rely on premium laminations.

Q5: What are common manufacturing challenges?

Maintaining thickness uniformity, precise cutting, consistent insulation, and accurate stacking are critical for high-performance laminations.

Premium motor laminations play a pivotal role in the performance and reliability of automotive and industrial motors. They reduce energy losses, enhance thermal management, and ensure mechanical integrity, directly influencing efficiency, noise, and operational lifespan.

As global energy regulations tighten and electrification expands, the demand for ultra-thin, high-quality, and precisely manufactured laminations continues to grow. Manufacturers who prioritize material quality, advanced production processes, and trusted supplier partnerships can produce motors that meet modern efficiency standards, minimize operational costs, and provide consistent, high-performance operation across diverse applications.

版权所有 © 浙江鑫峥机电科技有限公司 All RIGHTS RESERVED

本网站使用 cookie 来确保您在我们的网站上获得最佳体验。