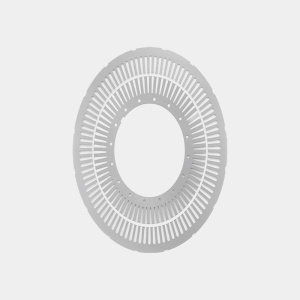

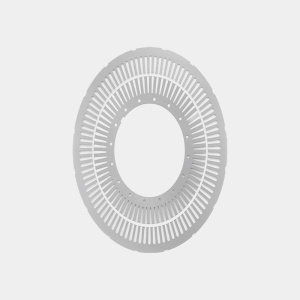

Y2 series motor rotor laminations price

Pricing Analysis of Y2 Series Motor Rotor Laminations The pricing of Y2 series motor rotor laminations is influenced by multiple factors, including material costs, production processes, design specifications, and market demand. Below is a detailed breakdown of the key elements affecting their price: 1. Material Costs The primary material used for rotor laminations is electrical steel (silicon steel), which accounts for a significant portion of the total cost. The grade and thickness of the steel (typically 0.35mm to 0.5mm) impact performance and pricing. Higher-quality silicon steel with lower core loss properties commands a premium price. Additionally, fluctuations in global steel prices due to supply chain disruptions or trade policies can lead to cost variations. 2. Manufacturing Process Rotor laminations are produced through precision stamping or laser cutting, followed by stacking and insulation treatment. The complexity of the rotor design (e.g., number of slots, shape, and size) affects tooling and production costs. High-volume orders typically reduce per-unit costs due to economies of scale, while custom or low-volume batches may incur higher prices. 3. Design Specifications The Y2 series follows specific efficiency and performance standards, influencing lamination dimensions and tolerances. Tighter tolerances and advanced coatings (such as insulation varnish) to reduce eddy current losses may increase costs. Additionally, rotor lamination stacks must meet precise balancing requirements, adding to production expenses. 4. Market Demand & Competition Pricing is also shaped by market dynamics. Increased demand for energy-efficient motors can drive up costs, while competition among suppliers may lead to price reductions. Regional factors, such as labor costs and logistics, further influence final pricing. 5. Additional Cost Factors - Surface Treatment: Insulation coatings or heat-resistant treatments add to material expenses. - Quality Control: Strict testing for dimensional accuracy and magnetic properties increases production costs. - Packaging & Logistics: Bulk shipping or specialized packaging for corrosion protection affects pricing. Conclusion The price of Y2 series rotor laminations varies based on material selection, production efficiency, design complexity, and market conditions. Buyers should evaluate suppliers based on quality, lead times, and cost-effectiveness to ensure optimal value. For precise pricing, manufacturers typically provide quotations after reviewing technical specifications and order volumes.

产品

分类:

-

硅钢片

所属分类: 冲片、散片浏览次数: 144编号:发布时间: 2025-09-30 15:12:27硅钢片:特性、应用和制造工艺硅钢片又称电工钢或变压器钢,是一种广泛应用于电气、电子行业的特种材料。其独特的性能使其对于需要高效能量转换的应用(例如变压器、电动机和发电机)来说是不可或缺的。本文探讨了硅钢片的特点、制造工艺和关键应用,强调了其在现代技术中的重要性。一、硅钢片简介硅钢片是一种含硅(通常在 1% 至 6.5% 之间)的钢合金。硅的添加显着增强了材料的电阻率,并减少了涡流和磁滞引起的能量损失。这些特性使硅钢叠片非常适合用于能源效率至关重要的电磁设备。术语“叠片”是指堆叠硅钢片以形成电机核心的过程。通过使用层压板而不是实心块,制造商可以最大限度地减少涡流损耗,涡流损耗是在交变磁场在导电材料中感应出循...

新闻

分类:

暂无搜索结果!

案例

分类:

暂无搜索结果!

视频

分类:

暂无搜索结果!

下载

分类:

暂无搜索结果!

招聘

分类:

暂无搜索结果!

推荐产品

暂无搜索结果!

手机:+86 13738592999

手机:+86 13738592999 电话:+86(576) 89307999

电话:+86(576) 89307999 邮箱:sales@zjxinzheng.com

邮箱:sales@zjxinzheng.com 地址:浙江省台州市三门沿海工业城

地址:浙江省台州市三门沿海工业城

Whatsapp

Whatsapp 电话

电话