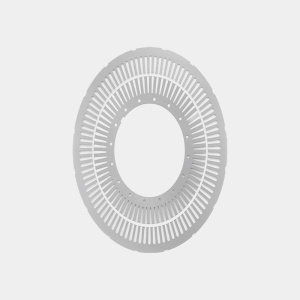

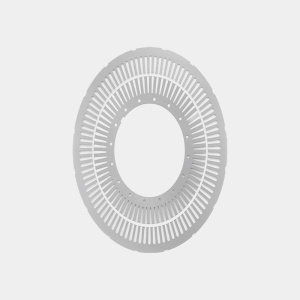

Y2 series motor rotor laminations suppliers

Y2 Series Motor Rotor Laminations Suppliers Overview The Y2 series motor is a widely used three-phase asynchronous motor known for its efficiency, reliability, and cost-effectiveness. A critical component of these motors is the rotor lamination stack, which plays a vital role in reducing energy losses, improving magnetic flux distribution, and ensuring smooth operation. Suppliers of Y2 series motor rotor laminations must adhere to strict material, design, and manufacturing standards to meet industry requirements. Material Selection High-quality rotor laminations for Y2 motors are typically made from silicon steel (electrical steel) due to its excellent magnetic properties and low core loss. The material grade, thickness (usually between 0.35mm and 0.5mm), and insulation coating (such as C5 or C6) are carefully selected to minimize eddy current losses and enhance motor efficiency. Suppliers must ensure consistent material quality to avoid performance variations. Precision Manufacturing Processes The production of rotor laminations involves precision stamping or laser cutting to achieve tight tolerances and smooth edges. Advanced tooling and die designs are essential to maintain dimensional accuracy, especially for the slots and keyways that accommodate rotor bars. Some suppliers also offer custom designs to meet specific motor performance criteria. Quality Control and Testing Reputable suppliers implement rigorous quality control measures, including dimensional inspections, material testing, and stacking factor verification. Eddy current testing and visual inspections ensure defect-free laminations. Proper stacking and alignment are crucial to prevent motor vibration and noise. Customization and Flexibility Suppliers often provide tailored solutions based on customer requirements, such as different slot configurations, stacking heights, or insulation treatments. Custom coatings or heat treatments may also be applied to enhance durability and performance. Global Supply Chain and Compliance Leading suppliers operate within a global supply chain, ensuring timely delivery and competitive pricing. Compliance with international standards (e.g., IEC, NEMA) is essential for manufacturers serving diverse markets. Conclusion Suppliers of Y2 series motor rotor laminations must combine advanced manufacturing techniques, strict quality control, and material expertise to deliver high-performance components. Their role is critical in ensuring the efficiency and longevity of Y2 motors across industrial, commercial, and automotive applications.

产品

分类:

-

硅钢片

所属分类: 冲片、散片浏览次数: 140编号:发布时间: 2025-09-30 15:12:27硅钢片:特性、应用和制造工艺硅钢片又称电工钢或变压器钢,是一种广泛应用于电气、电子行业的特种材料。其独特的性能使其对于需要高效能量转换的应用(例如变压器、电动机和发电机)来说是不可或缺的。本文探讨了硅钢片的特点、制造工艺和关键应用,强调了其在现代技术中的重要性。一、硅钢片简介硅钢片是一种含硅(通常在 1% 至 6.5% 之间)的钢合金。硅的添加显着增强了材料的电阻率,并减少了涡流和磁滞引起的能量损失。这些特性使硅钢叠片非常适合用于能源效率至关重要的电磁设备。术语“叠片”是指堆叠硅钢片以形成电机核心的过程。通过使用层压板而不是实心块,制造商可以最大限度地减少涡流损耗,涡流损耗是在交变磁场在导电材料中感应出循...

新闻

分类:

暂无搜索结果!

案例

分类:

暂无搜索结果!

视频

分类:

暂无搜索结果!

下载

分类:

暂无搜索结果!

招聘

分类:

暂无搜索结果!

推荐产品

暂无搜索结果!

手机:+86 13738592999

手机:+86 13738592999 电话:+86(576) 89307999

电话:+86(576) 89307999 邮箱:sales@zjxinzheng.com

邮箱:sales@zjxinzheng.com 地址:浙江省台州市三门沿海工业城

地址:浙江省台州市三门沿海工业城

Whatsapp

Whatsapp 电话

电话